Applications of CNC Turning

CNC turning is used in the production of cylindrical components such as shafts, bushings, rings, and threads. It is widely applied in industries such as:

- Automotive (production of drive shafts, engine components),

- Aerospace (precision turbine parts),

- Medical (components for medical devices),

- Electronics (enclosures and connectors).

How Does CNC Turning Work?

Step-by-step Turning Process

- Project Preparation

The process begins with creating a digital model of the part using CAD (Computer-Aided Design) software. The model is then converted into machine-readable code in a CAM (Computer-Aided Manufacturing) system. - Material Setup

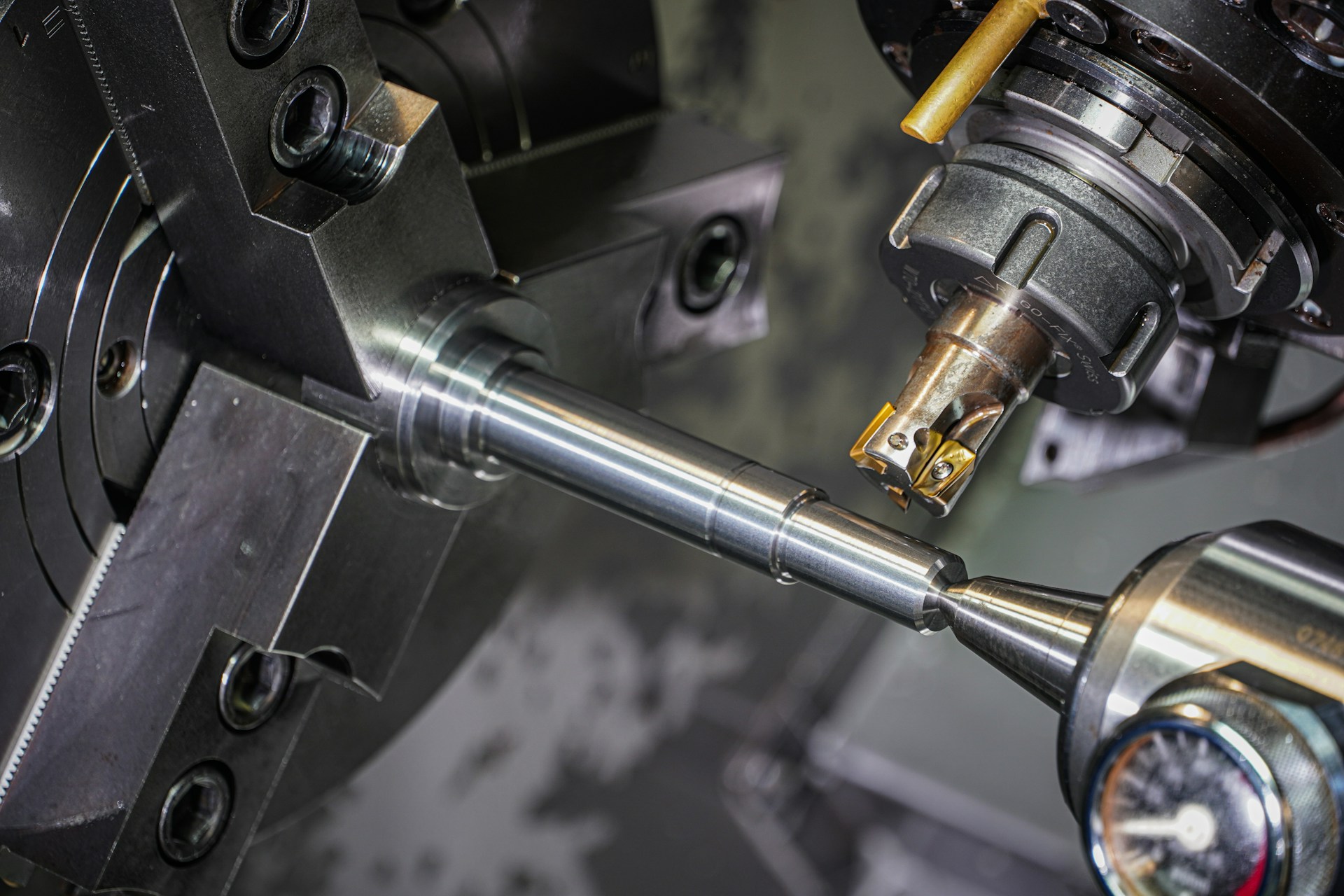

The raw material, typically in the form of a cylinder or rod, is clamped into the CNC lathe chuck. - Lathe Movements

- The workpiece rotates around its axis.

- The cutting tool moves along the X and Z axes, removing excess material and shaping the part.

- Parameter Control

All machine movements and settings (e.g., spindle speed, cutting depth) are controlled by the computer according to the programmed CNC code. - Finishing and Inspection

After machining, the part undergoes inspection to ensure it meets the design specifications.

Types of CNC Lathes

- Single-spindle lathes – Standard machines for simple components.

- Multi-spindle lathes – Enable simultaneous machining of multiple parts, increasing efficiency.

- Turn-mill centers – Combine lathe and milling machine functions, enabling more complex machining.

Benefits of CNC Turning

- Precision and Repeatability

CNC systems provide unmatched precision, which is crucial in the production of components with complex geometries and tight tolerances. - Efficiency

CNC lathes are extremely fast and can run continuously, allowing for high-volume production of identical parts in a short time. - Versatility

CNC turning can be applied to various materials, such as:- Metals (steel, aluminum, brass, titanium),

- Plastics,

- Composite materials.

- Cost Reduction

Automation minimizes the risk of errors and reduces waste, making production more cost-effective.

CNC Turning Applications in Various Industries

- Automotive Industry

CNC turning is used to produce shafts, pistons, bushings, and other precision components for engines and drive systems. - Aerospace Industry

Components like turbine shafts, bearing housings, and aircraft structural parts require the precision that CNC turning offers. - Medical Industry

CNC turning is indispensable in the production of implants, surgical instruments, and prosthetic components. - Electronics and Telecommunications

High-quality enclosures, connectors, and other small components are produced using CNC technology.

How to Choose the Right CNC Lathe?

Factors to Consider

- Type of Production

If you plan to produce large quantities of simple parts, a basic CNC lathe may be sufficient. For more complex projects, it’s worth investing in a turn-mill center. - Technical Specifications

Key parameters to consider are the machine’s accuracy, spindle speed, and available motion axes. - Cost

Although purchasing a CNC machine involves significant upfront costs, the investment pays off through increased efficiency and reduced waste. - Technical Support

Choose a machine from a reputable manufacturer that offers training and post-purchase service.

CNC turning is an advanced technology that has revolutionized the manufacturing industry, offering exceptional precision, repeatability, and efficiency. With its wide range of applications and potential for machining various materials, CNC turning has become an essential element of modern production. For companies seeking effective and efficient production methods, investing in CNC turning is a step into the future.

Interested in? Check out Propart from Poland, a company specializing in CNC milling and turning.